A LOOK AT THE HISTORY AND STYLE DIFFERENCES OF CONCRETE WINE TANKS

The world of viticulture is where tradition meets innovation and ancient craftsmanship harmonizes with modern technology. In this blog, we will journey through the world of concrete wine tanks, a timeless vessel that has become a symbol of both tradition and cutting-edge winemaking. As winemakers continually seek ways to enhance the quality and character of their wines, concrete tanks have emerged as a compelling choice, offering a unique set of benefits that contribute to the complexity and depth of the final product. We will look into the history, craftsmanship and advantages of using concrete wine tanks as we uncork the secrets behind this age-old yet remarkably contemporary winemaking technique.

The use of concrete tanks in winemaking goes all the way back to the 1900s. Back then, the giant tanks were poured on site and lined with an inert material and used for both the fermentation and aging of wines. Concrete tanks tend to be longer lasting, more sanitary, provide greater thermal stability, and help reduce temperature variations during the winemaking process. And unlike their wooden counterparts, they don’t harbor mold and bacteria that could compromise the wine.

While stainless steel tanks have been the chosen vessel for unoaked wines for the past several decades, winemakers across the country - and world - have looked to vary their preferences in the cellar. Over the past decade or so, more winemakers are turning to concrete tanks to bring a different flavor to the final product.

The trend of using concrete tanks has taken its hold in both the Old and New Worlds. In both regions, many winemakers feel the concrete’s sturdiness and quality of wine produced outweighs the upfront cost and bulk of the tanks.

In a 2018 article written by VinePair, there are some winemakers that started to feel stainless steel tanks were too sterile and produced sharp, linear wines that couldn’t breathe. On the other hand, the inside walls of the concrete tanks aren’t uniform. They tend to be “porous, with thousands of tiny pockets that trap air and allow the wine limited contact with oxygen.” Winemakers who want to maintain the freshness and purity of a grape’s character and don’t want any additional flavor in the wine would lean more toward using concrete tanks.

Flavor Difference

You may be wondering how different wine that is aged in a concrete tank compares to that of one that is aged in an oak barrel or even a stainless steel tank? When using oak barrels, the vessel itself imparts flavors to the liquid in the form of tannins and vanillins and spices. The “breathing” of the barrel over time allows an “array of chemical reactions that tweak and twist the flavors of the wine” that is in it.

On the other hand, a stainless steel tank has been the go-to neutral vessel for a long time. The stainless steel doesn’t allow air in and out of the container, which doesn’t allow it to interact with the wine over time.

According to wine experts, concrete tanks allow for micro-oxygenation - where the aging is similar to a barrel without imparting the aromas or flavors that come from oak barrels. Instead, concrete tanks offer a clean expression of the grape and its terroir.

Shapes and Sizes

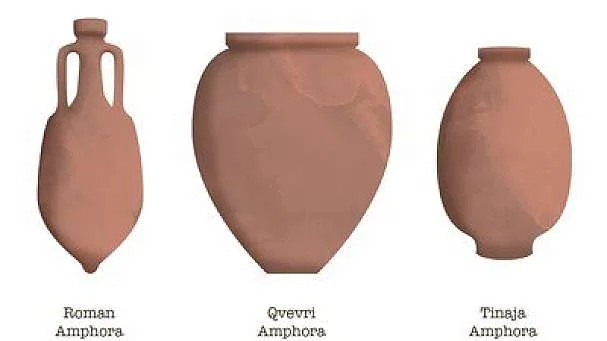

Concrete tanks are heavy, thick-walled vessels that come in many shapes and sizes. While there are several shapes these vessels can come in, the most common shapes are cubes, amphora, and egg-shaped. Let’s take a look at each shape and what they bring to the final product.

Ovoid Tanks

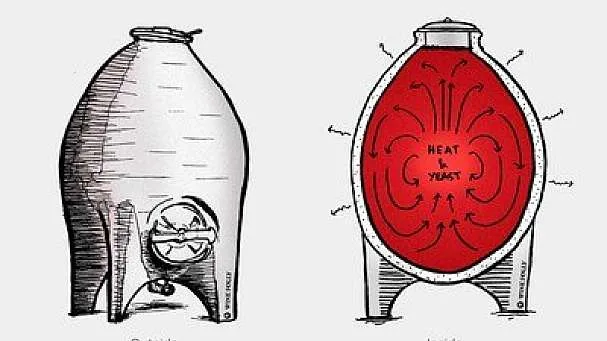

Let’s start our adventure with Ovoid - or egg-shaped - tanks. These tanks offer the benefits of the inherent micro-oxidation that is present in the porous natural cement composed of calcium and clay. According to Nombolt Wine Tanks, the large shape promotes suspension of the lees caused by the disparity of volume and temperature between the top and bottom of the tank.

Inside the tank, a vortex is created that has similar effects to stirring the lees, or battonage, and helps build body and structure in the wines. What is created from the large thermal mass of the concrete and the vortex movement of the wine is a container suited for consistent ferments as well as a porous aging vessel.

Concrete Amphoras

The unique shape of this vessel allows the wine lees to be kept in suspension which allows for the wine inside to build volume, concentrate its aromatic and express its fruit profiles.

The Romans would use large jars, or amphoras made from Terra Cotta, to ferment and age their wines. These vessels would help keep the wines a constant temperature and allow for a healthy fermentation of the grapes. The shape of this tank would allow the aging of the wine to happen with constant contact with its solids, build body and texture with minimal intervention because the winemaker doesn’t have to do pump overs or stir the lees.

The absence of hard angles in this tank helps promote circulation and keeps the solids in suspension during elevage - a French term for the progression of wine between fermentation and bottling. Elevage essentially “feeds” the mid-palate and brings richness to the product while polymerizing tannins.

Cubic Tanks

The shape of the cubic tank not only allows for the optimum utilization of space in the cellar, but it also offers several benefits to the wine.

These tanks offer only a slight micro-oxidation and allow a light passage of air to traverse the walls of the tank into the wine. Because of this, a softening of tannins and accentuation of the aromatic profile of the fruit and the terroir occurs.

These tanks can be found throughout France in almost all French appellations.

Good Harbor’s Program

This season, Good Harbor Vineyards has added 14 NuBarrel concrete tanks to our cellar program. Our tanks were produced by Sonoma Cast Stone Concrete Wine Tanks. Each tank holds about four barrels worth of wine - which replaces about 48 of the barrels in our barrel program.

Our Director of Winemaking Drew Perry hopes the concrete tanks added to our program bring a slower evaporation and greater de-acidification to the wines along with minimal maintenance and input from the production team. They will also help retain the pure expression of the fruit without the influence of the oak barrels unless our team decides to add it at a later time.

Please watch the YouTube video below to see how Sonoma Cast Stone Concrete Wine Tanks makes all their concrete tanks.

As we have learned, concrete wine tanks stand as a testament to the enduring fusion of tradition and innovation in winemaking. As we’ve explored the unique characteristics and benefits of these vessels, it becomes evident that they are more than mere containers; they are vessels of transformation. The porous nature of concrete allows for a gentle exchange between wine and its environment, fostering a slow and nuanced aging process. Beyond their functional advantages, concrete tanks contribute to the aesthetic of wineries, embodying a connection to the past while embracing modern craftsmanship. Whether it’s the rich history, sustainable aspects, ot the distinct flavor profile they impart, concrete wine tanks continue to carve a niche for themselves in the ever-evolving world of winemaking. As we raise a glass to innovation and tradition coalescing within the rugged walls of concrete, we celebrate the enduring legacy of these timeless vessels in the artistry of winemaking. Cheers to the ageless synergy between concrete and wine, forging a path that bridges the past and future of viticulture!